Project Clean Up

After years of engineering studies, detailed site investigations, and demolition of the former HoltraChem manufacturing plant in Orrington, the final phase of environmental remediation work began in 2014. The work is being led by Mallinckrodt US LLC (Mallinckrodt) and a team of several engineering firms with significant experience in and personal ties to Maine.

The goals for this remediation are:

-

Restoration of the land, allowing for reuse and development in the future;

-

Finishing the site work with zero injuries or adverse health effects;

-

Apply a safe, innovative, state-of-the-art approach to complete the remediation;

-

Prevent release of site contaminants to the surrounding environment;

-

Work cooperatively with the regulatory authorities; and

-

Contribute in a positive manner to the community.

All of these goals have been met to date, thanks to the work of dedicated professionals at Mallinckrodt, Maine DEP, and the contractors and consultants performing the work.

Meet the Remediation Team

In designing and implementing an appropriate remedy for the Site, the challenge was finding a team with the following qualifications:

-

experience in remediating chlor-alkali plants,

-

working with mercury contaminated soils and sediments,

-

excavating and capping landfills,

-

designing remedial plans and specifications.

-

understanding of Maine regulations

-

a history of working successfully with the Maine DEP were also top priorities

-

a proven track record of doing all the above in a manner that protects human health and the environment.

After extensive interviews, Mallinckrodt selected a team led by CDM Smith, Sevee and Maher Engineers and Geosyntec Consultants. Each of these firms, and the key individuals working at the Orrington Site, have specific professional experience working in Maine and on projects similar to the cleanup of the former HoltraChem chlor-alkali plant. Anchor QEA LLC, with its unique experience in river remediation, was also selected to perform the sediment remediation. Woodard & Curran, with its long expertise in water treatment, was selected to design, build, and operate the groundwater treatment plant.

Global Environmental Engineering Firm CDM Smith Takes the Lead in Orrington

-

CDM Smith is a Cambridge, MA based engineering firm which started in 1947 with expertise in water protection and treatment technologies. The firm expanded into an international company with a wide range of engineering and remediation projects.

-

In addition to its substantial remediation experience around the world, CDM Smith previously managed the dismantling of the former cell building and the subsequent demolition of numerous buildings and infrastructure at the site.

-

CDM Smith is responsible for overall project management and coordinating the work of Geosyntec, Anchor QEA, and various subcontractors.

Sevee & Maher's Expertise and Decades of Experience is a Perfect Match for Orrington Site's Remediation

-

Sevee & Maher Engineers, Inc. (SME) located in Cumberland, Maine was started in 1985 and includes environmental and civil engineers, geologists, data experts and groundwater modelers.

-

SME designed the initial groundwater extraction system at the Site, leveraging its expertise in hydrogeology, and geotechnical engineering fits well with other engineering firms working as part of the remediation team at the Orrington Site.

-

The complex geological setting at the Orrington Site presents certain engineering challenges, and SME is well qualified to address the hydrogeological aspects of the remedial designs.

Geosyntec Consultants Brings Maine Experience and an International Reputation to Former HoltraChem Site

-

Geosyntec is a consulting and engineering company founded more than 40 years ago, and includes scientists and engineers in a wide range of disciplines. The firm has been working in Maine since 1988 and opened an office in Augusta in 2002.

-

Geosyntec completed extensive work at the Crossroads Landfill in Norridgewock and consulted with the Maine DEP, literally writing the book (a manual) on the design and construction of final landfill covers.

-

Geosyntec has also provided consulting services related to the decommissioning and remediation of several other chlor-alkali facilities similar to the former HoltraChem facility.

Health and Safety is a Priority

While all environmental remediation projects require a health and safety plan before proceeding, each site has its own unique challenges. Therefore, any remediation plan needs to take into account site-specific considerations that may inform health and safety precautions. The HoltraChem remediation involved the excavation and removal of two site landfills and removal of contaminated site soils where the plant once operated. It also included the recapping of the three remaining landfills to permanently encase them, long after the remediation is completed, and the engineers have left the site.

Designed to protect the health and safety of site workers and the community around them, the Health and Safety Plan (HASP) is an expansive compendium of site health and safety concerns based on a defined and articulated goals:

-

No one is to be injured while on the job or exposed to unacceptable health risk;

-

Protect the surrounding air, soil, water, and sediment from any releases;

-

No violations of state or federal laws/regulations relating to the environment or worker safety.

The HASP for the Orrington site includes topics ranging from the specific responsibilities of the project manager and the Safety and Health Officer to preventing contamination and steps for decontaminating equipment – large and small –used to excavate site soils.

“The objective of a health and safety plan is to anticipate anything that could possibly go wrong and then build protocols and procedures to make sure that nothing goes wrong,” says Mallinckrodt’s Senior Remediation Program Manager. “They are highly trained professionals when they arrive on site, and they continue to train their employees and managers to adapt to the specific conditions of the project. We have a great deal of confidence in our team and in the plan they developed.”

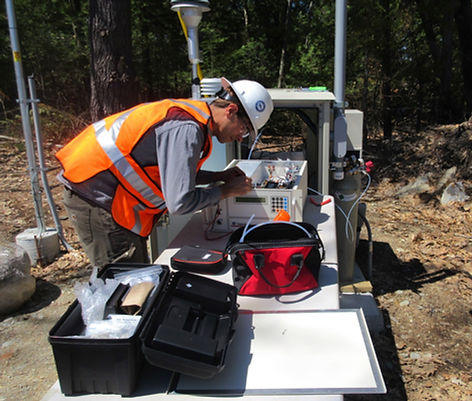

Site engineers have the benefit of constant air and groundwater monitoring that will detect any increase in mercury contamination while the excavation and removal process is ongoing. And they also have the advantage of CDM Smith’s long track record working at the Orrington site where they have acquired detailed knowledge of the site’s hydrogeology, terrain and soil from their work preparing the site for its final remediation and restoration.

Experience is an advantage, but experience at the very site where the work will take place is a great advantage.